YL Folder Gluer, XCS Folder Gluer, Folding Gluing Machine...

- Home

- XCS Series

- YL Series

- News

- About Us

- Video

- Contact Us

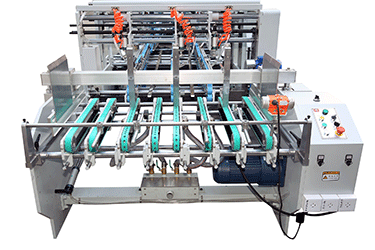

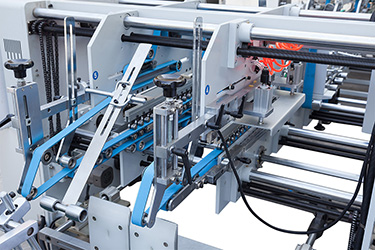

XCS-1100AC High Speed Lock Bottom Box Machine

Home >> Products >> XCS Series >> XCS-1100 Folding Machine >> XCS-1100AC High Speed Lock Bottom Box Machine1.Equipped with full color touch screen monitor system, the main machine, and conveyor can control the speed automatically and trace the parameter setting system synchronously.

2. Equipped with mobile adjustment for each plate , elaborate screw rod design, easy and fast operation by one people , high efficiency.

3.High efficiency speed conversion and powerful electric motor, equipped with strong belt for power transmission, high efficiency, low voice, easy maintenance and economic benefit.

4.Standard general side stick , double sides and lock bottom folding , elaborate design, easy and fast operation.

5.The upper and lower glue tank equipped with unique design for special box.

6. The press folding and conveyor equipped with adjustive pressure design for special products and a set of special soft belt for average pressure to ensure the perfect quality.

7. Photo-electric count, viable and quantitative count, equipped with kick board identification equipment

| Model | XCS-1100AC |

| Suitable paper | 200-800 g / ㎡ cardboard, E, F, N corrugated board |

| Box type | Straight-line box, double sides box, crash-lock bottom,flat box |

| Feeding way | Automatic continuous air suction for paper feeding. |

| Paste type | Solute type |

| Max. speed | 250m/min |

| Power | 24.5KW, AC220V/380V |

| Weight | 8500kg |

| Machine size | 17400mm*1900mm*1600mm(L*W*H) |

| Inching speed | 40m/min |

| Compressed air | 6 bar |

| Air compressor capacity | 10m/3 |

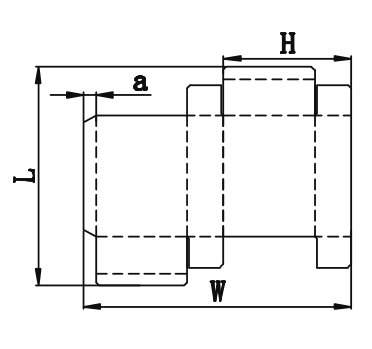

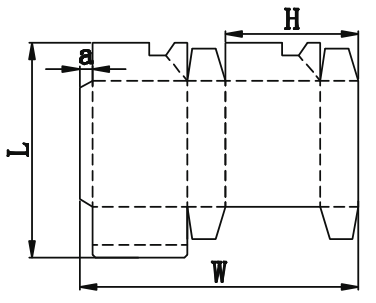

| Straight line box | Max/mm | Min/mm |  |

| L | 800 | 180 | |

| W | 1100 | 380 | |

| H | 540 | 180 |

| Crash lock box | Max/mm | Min/mm |  |

| L | 800 | 180 | |

| W | 1000 | 400 | |

| H | 470 | 190 |

| The flat box | Max/mm | Min/mm |

|

| L | 500 | 250 | |

| W | 1050 | 360 | |

| H | 520 | 180 |

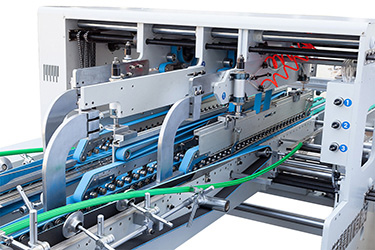

Feeder

>Paper feeding independent motor frequency control

>Main motor speed ratio linkage, pasting box process to keep the box spacing stable.

>Equipped with air suction, ensuring feeding accuracy.

Final-folding section

>Lengthening final-folding section, pneumatic adjusts pressure.

>Equipped with taper pulley (right and left) adjusts the speed of belt.

>Middle plate can be equipped with optional outer belt.

>Mini-box can be made on the left.

Output section

>Upper and lower drive mechanism for lengthwise adjustment.

>Equipped with belt tension automatic adjustment system.

>Pneumatic lifting, can quickly adjust the pressure

Conveyor

>Pneumatic adjustment of pressure, effective to facilitate the box paste.

>Conveyor speed according to the host speed with the photoelectric.

>Automatically or manually adjust.

>Depending on the length of the box, the upper part of the conveyor is equipped with a motor that moves back and forth.

Daphne Zhang

Daphne Zhang

Copyright © Dongguan XCS Machinery Co., Ltd. All Rights Reserved | Sitemap | Powered by