YL Folder Gluer, XCS Folder Gluer, Folding Gluing Machine...

- Home

- XCS Series

- YL Series

- News

- About Us

- Video

- Contact Us

YL-1650PC-A High Speed Automatric Apparatus Thick Carton&Box Folding Gluing Machine

Home >> Products >> YL Series >> YL-1650 Folding Machine >> YL-1650PC-A High Speed Automatric Apparatus Thick Carton&Box Folding Gluing Machine1.Equipped with full color touch screen monitor, main machine, transfer and conveyor can control the speed automatically and synchronization trace parameter setting system.

2. The machine adopt movable and adjustable operating function in each section .Equipped with elaborate tooth lever design. It is simple, convenient and efficient for one man operation.

3. High power stepless speed control frequency conversion and high-efficiency power motor, the highest speed can reach 400 meters/min, power transmission adopts powerful belt transmission, with low noise, high efficiency, easy maintenance and economic efficiency.

4. Each functional components of the machine adopt modular design, which is convenient to assemble, convenient to replace and debug products, convenient for beginners to master technology, and easy to learn.

5. Unique design of the upper and lower glue tank and coordinate with the need of products.

6. Compression and conveyor section equipped with adjustable the pressure design according to the needs of the products. Equipped with a set of special soft belts to ensure uniform pressure and perfect quality.

7. The machine adopt photoelectric counting, which can be used for total or quantitative counting, and equipped with kicker mark recognition device.

| Model | YL-1650PC-A |

| Suitable paper | 200-800 g / ㎡ cardboard, E-F-N corrugated board |

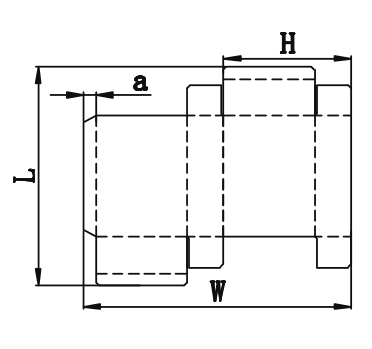

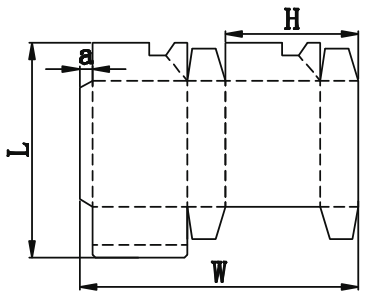

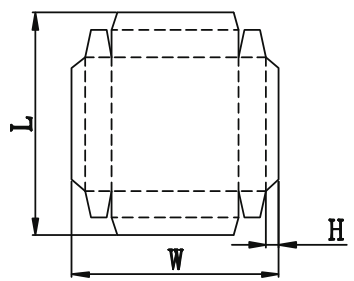

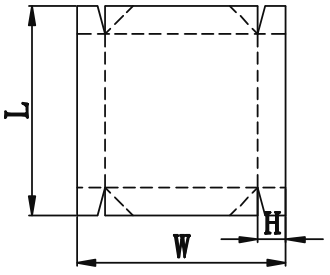

| Box type | Straight line, crash-lock bottom, double sides, optional four/six corner box |

| Feeding way | Continuous automatic feeding. |

| Glue type | Solute style |

| Max. speed | 400m/min |

| Power | 36KW, AC220V/380V |

| Weight | 13T |

| Dimension | 19000mm*2600mm*1600mm(L*W*H) |

| Inching speed | 40m/min |

| Compressed air | 6 bar |

| Air compressor capacity | 10m/3 |

| Air tank capacity | 60L |

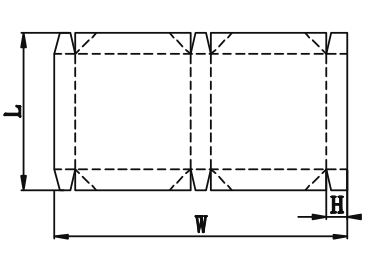

| Straight line box | Max | Min |  |

| L | 1000mm | 100mm | |

| W | 1650mm | 180mm | |

| H | 815mm | 85mm |

| Crash lock box | Max | Min |  |

| L | 1000mm | 100mm | |

| W | 1600mm | 200mm | |

| H | 790mm | 95mm |

| Double sides box | Max | Min |  |

| L | 1000mm | 140mm | |

| W | 1400mm | 220mm | |

| H | 50mm | 15mm |

| Four corner | Max | Min |  |

| L | 1000mm | 140mm | |

| W | 1600mm | 180mm | |

| H | 150mm | 30mm |

| Six corner | Max | Min |  |

| L | 1000mm | 140mm | |

| W | 1600mm | 280mm | |

| H | 150mm | 30mm |

Climbing section(optional)

>One-button electric lifting, easy to understand and operate, greatly improving production efficiency and achieving more stable folding.

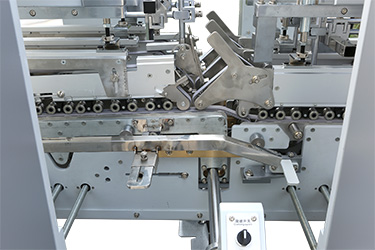

Final folding unit

>Smoothly and accurately finish the second fold line, the fourth fold line 180 °combined.

>Outer folding belts adjustable up to 180°with variable speed.

>Two upper and two lower carriers with 25mm lower and 30mm outer belts.

>Width wise adjustable heavy duty compression rollers.(optional)

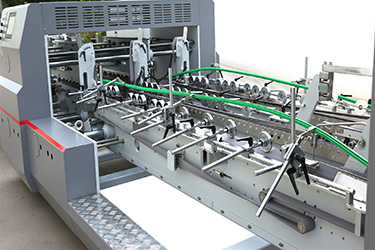

Output unit

>Upper and lower drive mechanism for lengthwise adjustment

>Equipped with automatic belt tension-adjusting system

>Continuous and automatic box collection mechanism that ensures a neat transfer to the press section, guaranteeing a well aligned flow.

Servo motor anti-hook device(optional)

>The two sets of servo axis ensure that the anti-hook folding movement is accurate, and the setting can be easily completed by the touch screen.

Daphne Zhang

Daphne Zhang

Copyright © Dongguan XCS Machinery Co., Ltd. All Rights Reserved | Sitemap | Powered by